型号 Type

参数 Parameter | SLD1S1K-10mA/RS485 |

单位 |

额定输入电流(Ipn) Rated input current (Ipn) | ± 10 | mA |

测量电流范围(Ipm) Measuring Current Range (Ipm) | 0~ ±80 | mA |

输出接口 Output interface | RS485 | |

分辨率 Resolution | 10 | uA |

波特率 Baud rate | 9600(无校验) | bps |

电源电压 (Vc) Supply voltage (Vc) | +8~+12 | VDC |

功耗电流(Ic) Power consumption current (Ic) | @8VDC ,K1 、K2 开 ≤20mA | mA |

精度(X) Accuracy (X) | ± 1 | %FS |

线性度 ( ε) Linearity (ε) | ≤1 | %FS |

失调电流(Ioe) Offset current (Ioe) | ≤±250 | uA |

温漂(TC) Temperature bleaching (TC) | 20 | uA/℃ |

刷新时间(tr) Refresh time (tr) | ≤500 | mS |

操作温度(TA) Operating temperature (TA) | -10 to +70 | ℃ |

存储温度(TS) Storage temperature (TS) | -10 to +75 | ℃ |

绝缘电压(Vd) Insulation voltage (Vd) | @ 50HZ/60HZ ,1min 3 | KV |

绝缘阻抗(Ris) Insulation impedance (Ris) | @ DC 500V 500 | M Ω |

爬电距离(dCp) Creepage distance (dCp) | 13 | mm |

空间间距(dCi) Spatial Spacing (dCi) | 13 | mm |

应用 Application |

l 微电流检测

Microcurrent detection

l 直流电源系统绝缘在线监控

DC power system insulation online monitoring

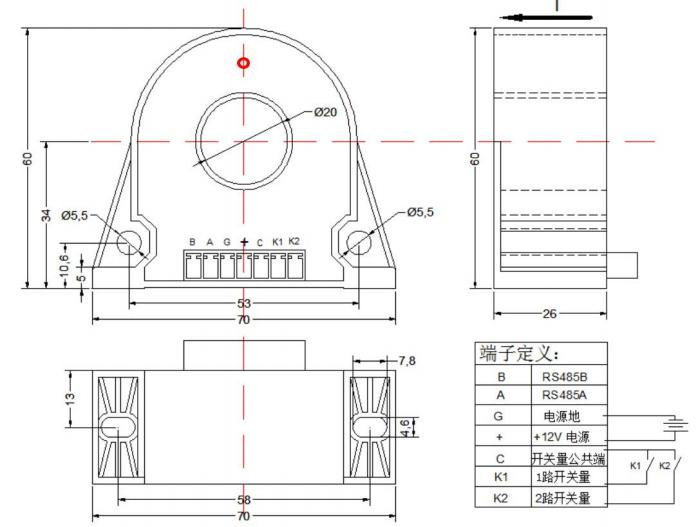

结构参数 Dimension

备注:所有尺寸单位 mm ,通用公差±1mm

Note: All dimensions in mm, general tolerance ±1mm

使用说明 Remarks

1.当待测电流从传感器穿过,即可通过 RS485 获取当前被测电流数据。

2.可按用户需求定制不同额定输入电流和输出电压的传感器。

3.本产品为弱电流检测产品,传感器容易受运输、测试环境等因素影响,零点会有变化,但 2V 以内不影响传感器 的线性度。建议客户在使用本产品时,将传感器安装到系统待传感器稳定后进行零点测试,当零点偏大时,进行软 件校零处理。也可用 2.0 无感一字螺丝刀进行电位器调零,直至零点恢复正常;再将系统报警值设置在 2V。

4.错误的接线以及超出产品测量电流范围可能导致传感器损坏。

1. When the current to be measured passes through the sensor, the current data can be obtained through the RS485 port.

2. Sensors with different rated input current and output voltage can be customized according to user needs.

3. This product is a weak current detection product, the sensor is easily affected by transportation, test environment and other factors, the zero point will change, but the linearity of the sensor will not be affected within 2V. When using this product, it is recommended that the customer install the sensor into the system and carry out zero test after the sensor is stable. When the zero is too large, carry out software zero correction processing. The potentiometer can also be zeroed with 2.0 non-inductive flat-head screwdriver until the zero point returns to normal; Then set the system alarm value at 2V.

4. Incorrect wiring and out of the range of product measurement current may cause sensor damage.

| Classify | Title | Download |

|---|

Leave your contacts and our engineers will help you to find the solution you are looking for.

Hi! Welcome back.

How are you doing?

Let’s talk! We’ll provide the perfect solution for you!

Shanghai Freesor Sensor Technology Co. ,Ltd. was founded in 2005 by a number of overseas returnees with rich experience. It is a high-tech enterprise integrating design, research and development, production and sales.

Sales Center Add: Room 1405-1, Building B, 333 Haiyang 1st Road, Pudong New Area, Shanghai

Factory Add:Building 4, Keland Smart Energy Industrial Park, Guangming District, Shenzhen, Guangdong Province, China.